Conduct a thorough assessment of your current systems and processes. Identify areas where OT can bring the most significant improvements. Develop a strategic plan that aligns with your business goals

- Need Assistance? We're Here to Help! Contact Us:

- phone (215) 335-3180 | (202) 844-0990

- emailinfo@tansatech.com

- access_time Mon - Fri: 8am - 6pm

Unlock the Potential of Your Business with Operational Technology (OT)

Operational Technology (OT) refers to hardware and software systems that detect or cause changes through direct monitoring and control of physical devices, processes, and events in the enterprise. Unlike traditional IT systems that manage data, OT focuses on the physical devices and processes critical to the functioning of manufacturing plants, power grids, transportation systems, and other industrial environments.

Key Components of Operational Technology

Operational Technology (OT) encompasses a range of essential components that ensure the efficient and reliable functioning of industrial and energy systems. Here are the key components:

Industrial Control Systems (ICS)

These are the backbone of OT, encompassing various types of control systems

and associated instrumentation used for industrial process control.

Examples include:

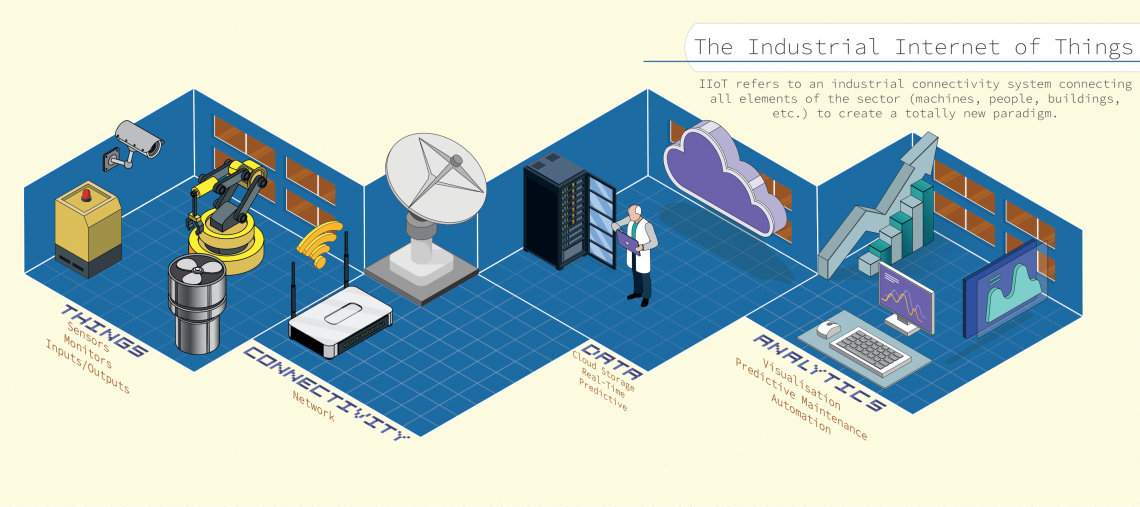

Real-Time Data Analytics

Real-time data analytics platforms process data from various sensors and devices to provide actionable insights. This can lead to improved operational performance and efficiency.

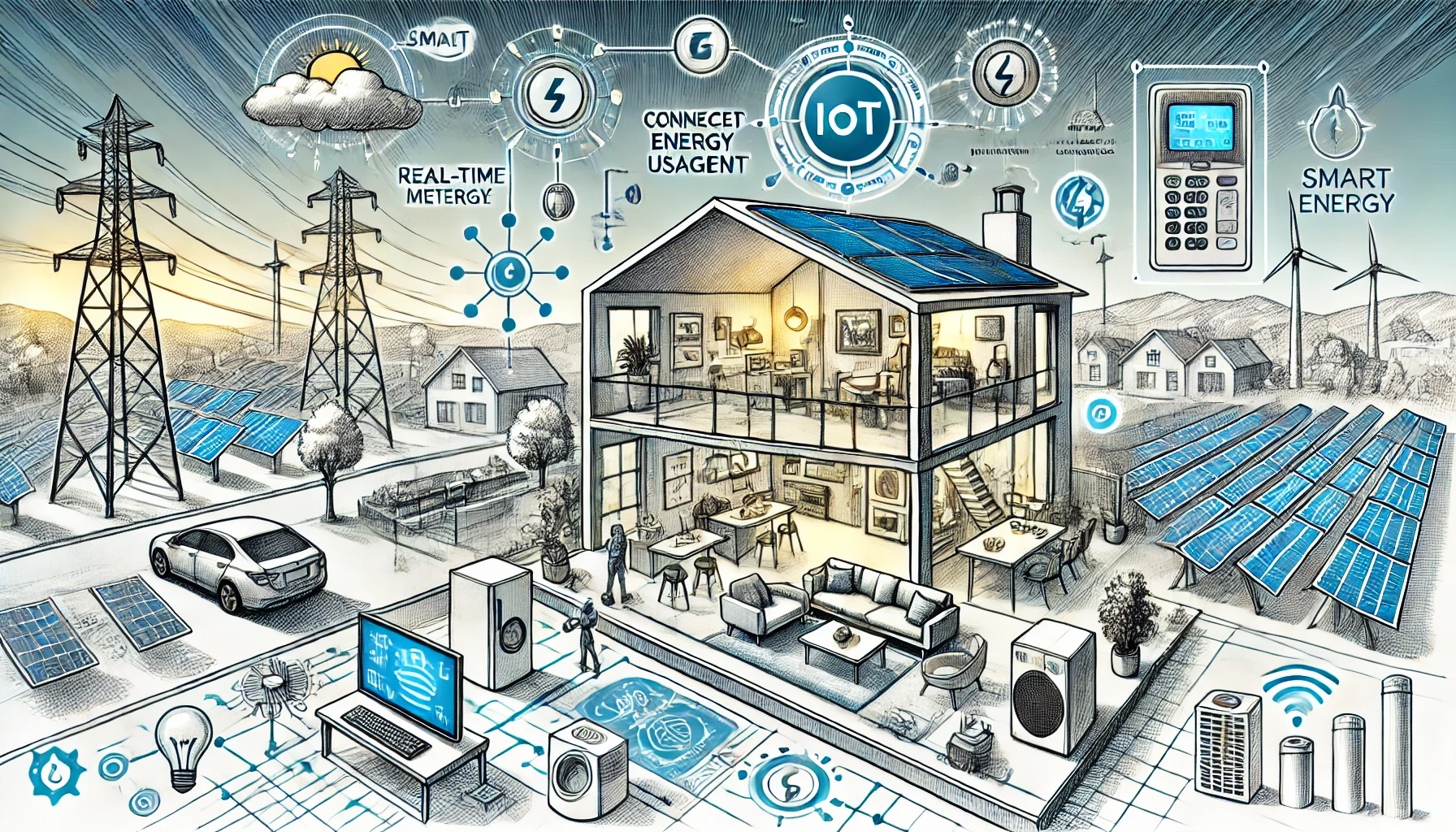

Internet of Things

IoT devices and sensors collect data from physical assets and transmit it to OT systems for monitoring and control. The integration of IoT with OT enhances visibility and control over industrial operations.

Cybersecurity Solutions

Securing OT systems from cyber threats is critical. Implementing robust cybersecurity measures ensures the integrity and availability of your operational technology infrastructure.

Why Operational Technology Matters

In today's fast-paced and technology-driven world, operationalizing your systems through OT can significantly enhance efficiency, safety, and reliability. Here are some compelling reasons to invest in OT:

- Improved Efficiency: Automate processes

- Enhanced Safety: Implement real-time monitoring and control systems to ensure the safety of workers and compliance with regulatory standards.

- Reduced Downtime: Predictive maintenance and real-time alerts help in anticipating failures before they happen, reducing costly downtimes.

- Data-Driven Decisions: Collect and analyze data from your operational processes to make informed decisions that boost productivity and reduce costs.

Steps to Operationalize Your Systems with OT

- Step 1: Assessment and Planning

- Step 2: Selecting the Right Technology

- Step 3: Implementation

Choose the OT solutions that best fit your needs. Consider factors such as scalability, compatibility with existing systems, and ease of integration.

Deploy the selected OT systems in phases. Start with a pilot project to test the functionality and gather feedback. Gradually scale up to full implementation.

- Step 4: Training and Support

- Step 5: Continuous Improvement

Provide comprehensive training to your staff to ensure they are proficient in using the new OT systems. Establish a support structure to address any issues that arise during and after implementation

Regularly monitor the performance of your OT systems and make necessary adjustments. Use data analytics to drive continuous improvement in your operations.